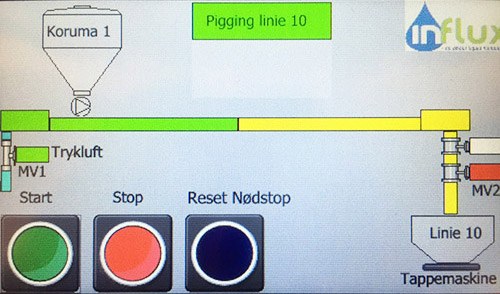

Principle

A projectile (called a pig) is forced through the pipeline, and because the pig’s diameter is slightly larger than that of the inner diameter of the tube, the pig forces the product through the tube while simultaneously cleaning the surface of the tube.

We have specifically designed the pig to be hygienic, highly effective and thorough. The system is ideal for transferring a product, product collection and cleaning. Influxes pigs can with ease move through bends, and only require a low propulsion pressure. What’s more, more than 99% of the product is collected.

The means of propelling the pig can be by water, sterile air, nitrogen or with the next product, in the case of a product change.

Traceable pigs

Our pigs have built in magnets, making them detectable throughout the piping system, with the use of specially designed pig detectors, and because our detectors are mounted on the exterior of the pipes, it’s fast, easy and cost efficient to add them to an existing piping system.

Our pigs have built in magnets, making them detectable throughout the piping system, with the use of specially designed pig detectors, and because our detectors are mounted on the exterior of the pipes, it’s fast, easy and cost efficient to add them to an existing piping system.

Besides being able to trace the pigs, a tracking system enables a semi- or full automation of the system. This would provide a significant increase in efficiency, productivity and safety.